We do things very accurately... and our testing is thorough, replicable and objective.

Components with a safety relevance demand quality assurance. Accordingly, an efficient quality management system and modern testing systems within the production process are indispensable. To make this quality standard externally verifiable, we have had our QM system certified according to DIN ISO 9001. Tests carried out during production (ultrasound testing, surface crack testing, dimensional inspections, hardness testing and similar) further ensure that the relevant component documentation is maintained and complete at every stage of the production process.

Materials Testing: Only by testing can quality be assured.

Technical developments are opening up unimagined possibilities. New types of steel, ever stronger, are appearing and so enabling building components to be made ever lighter. This trend, however, in turn requires a practice-orientated approach using powerful monitoring systems and extensive testing of relevant welding parameters in order to ensure that the required weld properties are achieved.

Accordingly, experiments carried out and evaluated in our laboratory, and the subsequent determining by our qualified personnel of the optimal welding parameters, are important conditions if the product is to be successful. We therefore place a high level of importance on careful materials testing. Such testing includes the following tests performed by us in-house.

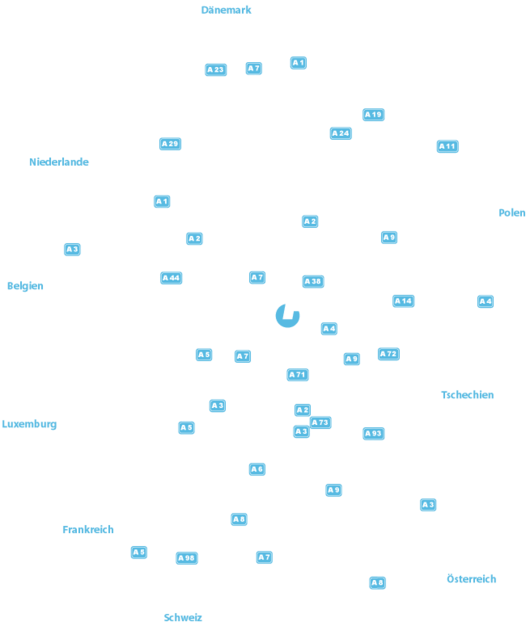

OUR COMPETENCES AT A GLANCE

- Cutting, shaping, mechanical processing and welding of high-strength fine-grained steels.

- Certified according to DIN EN ISO 9001, DIN EN ISO 3834-2, DIN EN 1090-2 to EXC3 and DIN EN ISO 50001

- Welding processes are qualified according to DIN EN ISO 15614 through to S 1100 QL

- Welder training in our internal training centres based at Gotha and Eisenach

- Licensed to offer temporary work